30+ years of service, retired with honors

Category: HB-03

Slowly closing in on the fun stuff. The brake assemblies all use plastic/nylon at the pivots! Well, they've lasted 30+ years. Sil-glyde for you.

I've read suggestions to grease friction shifters and suggestions to leave them dry. There's more nylon here (used as crush washers to add friction), though the lever faces directly contact metal washers on both sides. A bit of sil-glyde on those faces, and we'll see how it goes.

I planned to use marine grease for all bearings (metal on metal), but the bottom bracket has a plastic sleeve. I've yet to personally experience marine grease causing problems with plastics or rubber (after using it in a low-end coil suspension fork), but I'll probably err on the side of caution and use silicon grease here too.

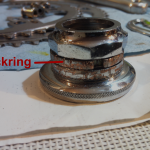

This headset turned into the build's "feature problem". The lockring wouldn't come off with my puny notch wrench, and I resorted to using deathgrip pliers (guh!). The fork threads and adjoining toothed spacer suffered collateral damage.

The fork threads were freed up easily enough, and it turns out 27" threaded forks are fairly cheap and widely available (if worse had come to worse).

But this three-notch lockring is a mystery. It isn't part of the retail Tange MA-60 stack or its (modern?) update, the MA-60C. The MA-60C itself shows up in a fairly recent Tange product catalog, but I've yet to find an aftermarket source for it (OEM-only item?).

I like the look of the knurled adjustable race, but a new one with wrench flats is probably the only practical way to go.